Chris-Marine Launches Advanced Camera For Cylinder Liner Condition Monitoring

Chris-Marine Launches Advanced Camera For Cylinder Liner Condition Monitoring

“The launch of our Cylinder Liner Condition Camera LCC is an important step for us and for our customers,” says Alexander Malt, Global Sales & Marketing Director, Chris-Marine.

“We know that at least 10% of new buildings need to have their cylinder liners replaced already before the first dry-docking, a costly consequence of failing to keep the liners in top condition. However, this problem can easily be prevented and that’s where our camera comes into play. LCC detects and documents abnormal surface conditions and helps the engine crew determine if measures need to be taken. By monitoring the condition of the liner regularly, severe damage to the engine can be prevented and unnecessary investments avoided, Alexander Malt continues.”

The condition parameters of the cylinder like the presence of cylinder honing marks and Wave cut groove extension, bore polish and black lacquering, cylinder wear edge size and the cleanliness of ring land can be evaluated by the pictures captured by the camera.

LCC provides images from BDC (bottom dead center) to TDC (top dead center).

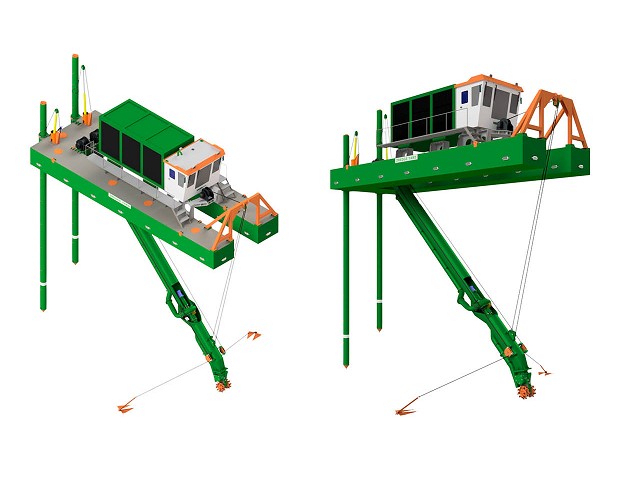

Cylinder Liner Condition Camera, LCC was launched today by Chris-Marine. LCC can be used for in situ photography of the cylinder liner walls and the exhaust valve in 2-stroke engines.

Also read: Is Career In Underwater Photography Lucrative?

About LCC

- The 4 inbuilt cameras in the LCC unit helps in the photography of the complete liner running surface, cylinder cover, lube oil injection area, exhaust valve, start air valve and injector valves.

- The LCC can provide documentation of in situ cylinder condition of 2-stroke engines with a bore size from 480 to 980 mm.

- To allow operations without the temperature of the engine coolant to lower for most types of engine the LCC is made up of high-temperature-resistant electronic components and batteries.

- 14 cylinders can be documented using fully charged batteries and the time required per cylinder is approximately 15 minutes.

- LCC also has tools for centering, inserting and extracting the camera and checking clearance at TDC.

- LCC can be used without removing cylinder cover or exhaust valve housing.

- The LDM tablet can be used to combine LCC with Chris-Marine’s Liner Diameter Measurement Instrument LDM.

Reference: Chris-Marine