Höegh Proves Its RoRo Solutions To Be Best Fit For Breakbulk Units

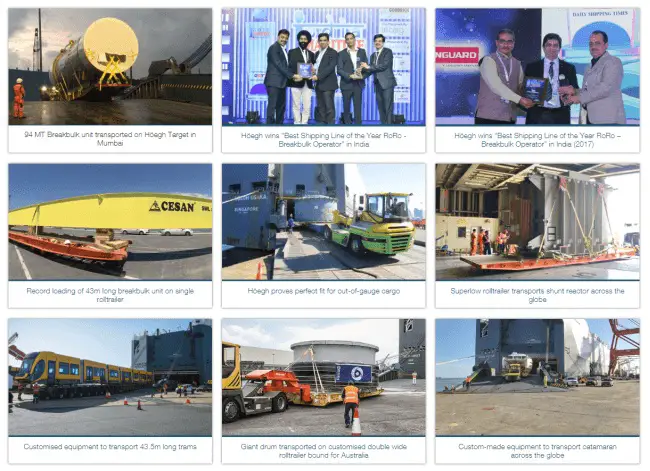

Recently Höegh Autoliners India transported a 94.3 MT Mill Shell for a cement plant project in Mali Senegal. The customer was looking for the most efficient option to transport their cargo and turned to Höegh Autoliners with its direct service and extensive experience in shipping Breakbulk.

Timely service and low risk

With the customers’ tight deadline, Höegh Autoliners’ direct RoRo (Roll on/Roll off) service from Mumbai to Dakar proved a perfect fit for transporting the breakbulk unit, ensuring a timely service with minimum transit time.

The customer had used LoLo (Lift On/Lift Off) vessels in the past for their shipments but swapped to RoRo, because the operation would be safer and more reliable. The cargo would be directly rolled on and off the vessel, eliminating the need for crane lifting in both load and discharge ports. This reduces the risk of damage to the cargo and ensures a safer and more efficient operation.

In addition, due to the sensitivity of the cargo, it would be safely stowed under deck where it would not be exposed to weather or seawater. This meant that the customer would not need to pack the breakbulk unit, saving them a considerable cost.

Challenge presented

A challenge, however, was presented as due to the dimensions of the breakbulk unit, primarily the length to weight ratio, it would not be possible to load on Höegh’s 62 feet rolltrailer. The entire cargo weight was resting on only two saddles which meant that the stress on the 100 MT rolltrailer was above the workable limit. To add to this, the total height of the cargo measured 5.75m. This meant that the only vessels that could ship the cargo was Höegh’s Post-Panamax vessels, which are capable of transporting cargo up to 6.5 m high.

Solution developed

Geir Paulsen, Head of Global Breakbulk Solution says,

Experience is critical, and it was clear that a customised solution was needed to get the breakbulk unit on board. We contacted the rolltrailer manufacturer and came up with a solution to use steel beams under the cargo to distribute the load across the length of the rolltrailer and reduce the stress.

With supervision from Höegh Autoliners’ Port Captain on site, and with the customer present, the Mill Shell was safely loaded on board Höegh Target in Mumbai, ready for its ocean voyage to Dakar.

Atuldutt Sharma, Breakbulk Sales Manager, Höegh Autoliners India says,

The customer was very impressed with the service, level of professionalism and technical expertise provided. This shipment was a perfect example of our dedicated focus and constant innovation to develop Hoegh as a leading carrier for breakbulk cargo.

Experience is critical, and it was clear that a customised solution was needed to get the breakbulk unit on board. We contacted the rolltrailer manufacturer and came up with a solution to use steel beams under the cargo to distribute the load across the length of the rolltrailer and reduce the stress.

With supervision from Höegh Autoliners’ Port Captain on site, and with the customer present, the Mill Shell was safely loaded on board Höegh Target in Mumbai, ready for its ocean voyage to Dakar.

Atuldutt Sharma, Breakbulk Sales Manager, Höegh Autoliners India says,

The customer was very impressed with the service, level of professionalism and technical expertise provided. This shipment was a perfect example of our dedicated focus and constant innovation to develop Hoegh as a leading carrier for breakbulk cargo.

Press Releases: hoeghautoliners.com

Photo Courtesy: hoeghautoliners.com