What Is The Hull Of A Ship?

The following article discusses the hull of a ship, what it is, how it is made, and what it means for the building of a ship. It also talks about how the hull of the ship is built by carrying out several mathematical calculations and taking into consideration, several other factors.

What is the hull of a ship?

The hull of a ship is the most important as well as the most noticeable part of the ship. It is the watertight part of any vessel or even boat. It is defined as the water-tight enclosure of a ship. It protects the cargo and the machinery of the ship. It can also protect the boat from flooding and other structural damage. It is the part of the vessel which meets the ocean. The point or the line at which the hull of a ship meets the surface of the water is called the waterline.

The hull of a ship can vary greatly depending upon the size or the type of the ship or vessel.

Any structure like the deck of a ship, the mast, etc. can lie above or atop the hull of a ship.

The following article talks about how the hull of a ship is designed, the factors that are taken into consideration while doing so, and what kind of a role it plays in the life of the ship as a whole.

Parts of the hull of a ship

Here are some of the basic parts of the hull of a ship:

a) Bow and Stern

The bow of a ship is defined as the forward part of the hull of the ship. Normally, it is the forward-most part of the ship when the vessel is underway. The stern of a ship is the exact opposite of a bow. It is the back part of the ship or the aft-most part. It extends upwards from the counter rail to the taffrail. It lies opposite to the bow.

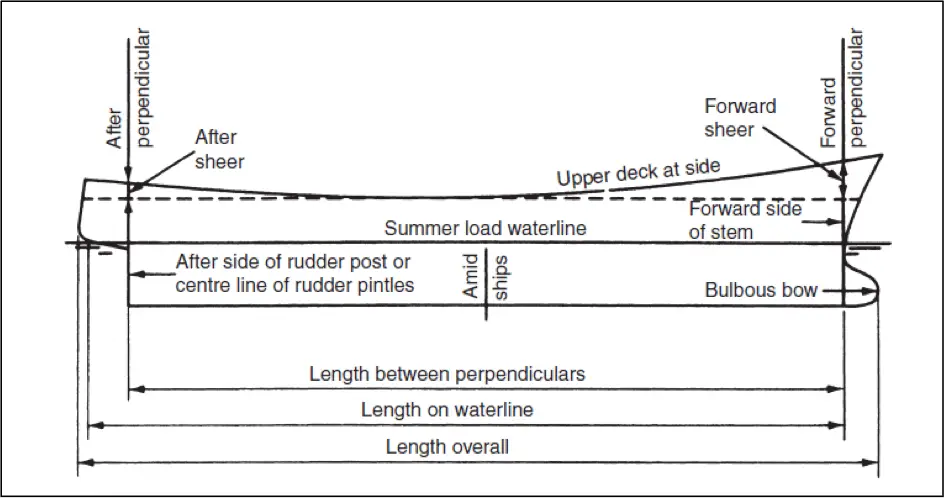

b) Forward Perpendicular

A forward perpendicular is an imaginary perpendicular line. A perpendicular line is defined as the line which touches or intersects another line with an angle of 90°. It is also called a right angle. The forward perpendicular of a ship is the perpendicular drawn from the point where the bow of the ship intersects the waterline.

c) Length between perpendiculars

If a perpendicular is drawn from the forward end of the ship that is the bow and another perpendicular is drawn from the aft end that is the stern, then the length between the two perpendiculars is known as the length between perpendiculars.

d) Sheer

Sheer is a term used in naval architecture. It is the length of the longitudinal main deck curvature of the ship. The main purpose of it is to allow the flow of green water from the bow or the stern of the ship to the middle of it and to allow the drainage to go to the bilges. The forward end of the ship usually has more sheer in order to protect the machinery there from the waves of the ocean.

e) Summer load line

A summer load line is defined as the waterline of a ship when it is at its full weight that is it is fully loaded. It is also called the design draft. The summer load line acts as a reference for all the other load lines on a vessel or a ship.

f) Length of water line

The length of the hull of the ship when it is fully loaded that is it is at the summer load line of the ship is referred to as the length of the waterline. The length of the waterline is a very important factor in calculations related to propeller designs and other hydrostatics of the ship.

g) Length overall

The total distance between the forward-most point of the hull of the ship and the aft-most point of the hull of the ship is referred to as the length overall or the overall length. This length plays a vital role in planning the docking and undocking of the ship.

Lines and Shapes of the Hull of a ship

The first and the most essential part of building the hull of the boat is planning the design of the ship and the form of the vessel. To do this, several mathematical calculations are carried out. Following are some of the mathematical quantities that help us do the same.

a) Block Coefficient

The block coefficient of a ship is a numerical quantity that is obtained by dividing the underwater volume of displacement of any vessel by the volume of a block that has the same length, breadth, and height as the draught of the ship. It highly depends on the lines of the ship. It is abbreviated as Cb. For a typical ship, the block coefficient has to be less than one. The higher the value of the block coefficient, the fuller is the hull form of the ship. Container Ships or warships generally have a low value of block coefficient.

b) Midship Coefficient

The midship coefficient of a vessel is defined as the ratio of the submerged midship area to the product of the beam at the mixture and the draft of the ship.

c) Prismatic Coefficient

The prismatic coefficient of a ship is the ratio of the volume of displacement at the draft to the volume of a prism. The prism is assumed to have the same length as the length of the ship and the same area of cross-section as the area of the midship of the vessel.

d) Waterplane Coefficient

The waterplane coefficient of a ship or the waterplane area coefficient of a ship is defined as the ratio of the actual area of the water plane of the ship to the product of the length and the breadth of the ship.

There are several such other coefficients that are used as parameters to carry out important calculations on ships. These calculations help to develop the hull lines.

Buttocks and Waterlines

If we longitudinally cut the entire hull of a ship into several sections, the boundary of each of the sections is called a buttock line. The waterline of a ship, as stated before, is the line at which the hull of the ship meets the surface of the ocean.

If the entire hull of the ship is cut along the waterline, then a distinctive part or area will be produced by every water line. A diagrammatic representation of the same is known as the body plan of the ship. It is also known as the half breadth plan of the ship. Thus, the body plan of a ship is obtained by slicing the hull of a ship at equal intervals.

It is very important to note that in order to have a proper shape of the hull of the ship and to make the propeller efficient, the shape of the water lines plays a very important role.

The body plan is the most important as well as the most useful representation of the hull lines of the ship. It is so important that the body plan and the reference lines are sufficient to develop the entire profile plan and half breadth plan of the ship. The body plan of a ship can also be used to develop a sectional area curve and Bonjean curves of the vessel. The lines in the body plan can help to develop a three-dimensional hull model as well as frame by structural drawings, loft drawings at the shipyard, and general arrangement.

How to design the structure of the hull of the ship?

Following are the steps are taken in order to design the hull structure and strength of a ship.

Step 1: The first step in designing the hull structure is the calculation of the loads on it. There are many specialized formulae available for calculating the wave loads on the hull of a ship. These formulae take into consideration the bending moment of Stillwater, wave bending moment, and shear forces. These are used to derive the load values which act as set points in the entire process of structural design.

Step 2: The second step is the scantling calculations for midship. Scantling collectively refers to the dimensions of all the structural members of the ship such as plates, beams, pillars, stiffeners, girders, etc. These are derived with the help of the load calculated in the first step. This process is carried out at every frame.

Step 3: The third step is called the midship section modulus. In this step, the midship section structural drawing is made by taking into consideration all the calculated scantlings. After this, the neutral axis is located, and the section modulus of the mid subsection is calculated. There are two criteria that need to be satisfied with this. Firstly, the midship section that is obtained should be equal to or more than the minimum section value which is obtained using the empirical formula in the rule book. Secondly, the stress values are needed to be calculated and it is ensured that the stress values are within the required range of safety.

Step 4: In the fourth step, a frame-wise scantlings calculation is done. This means that the scantlings are calculated at each frame to prepare the corresponding frame-wise structural drawings. Several formulae are used for this.

Step 5: In this step, the weight of the steel is calculated. This is done with the help of the obtained scantlings. Here, if the weight of the steel is crossing the statistically and empirically calculated values, the designer of the ship should do something to make it light like using lighter weight steel that lies within the limits.

Step 6: This is the final and the most important step in which the three-dimensional model of the hull of the ship is created. This is done with the help of the drawings of each frame. This is the most time-consuming step in the entire process. It is critical for this model to be accurate as the real resulting ship entirely depends on it. This step is carried out very carefully and analytically. The design of the vessel is approved or disapproved based on this model.

The course stability of the hull of the ship

The course stability of the hull of the boat or rather the course keeping ability of it is another significant factor. The following aspects are evaluated to evaluate the maneuverability of the ship.

a) Straight line stability

A hull is said to have straight-line stability if when a ship is moving in a straight line and changes directions due to some external disturbance but continues to travel in a straight line.

b) Directional stability

A ship is said to have directional stability if when it is subjected to an external disturbance and is compelled to change its path but continues to move in a path that is parallel to the original one.

c) Path stability

A ship is said to have path stability if it continues to move along the same path after few oscillations when it is subjected to an external disturbance. Path stability and directional stability can only be obtained when there is straight-line stability.

Hence, the main objective of building the hull of the ship is so that the ship can have straight-line stability. To make the model of a hull alone, so many factors are taken into account. We have discussed many of them in this article. However, there are some more aspects that need to be kept in mind while talking about making the model of the hull of a ship. These include calculation of hull resistance, watertight integrity, intact stability, vibration and dynamic responses, longevity at sea, etc.

So, we can see how much mathematics is required to build just one ship. These calculations have been carried out since the oldest of times. We can imagine how difficult it is to build only one ship. Thus, we can fathom the intellectual capabilities of the people who work for the shipping industry. This is more proof that a career in the Marine Industry is so demanding and yet one of the most sought-after and rewarding careers in the world today.

Fremont provides the best Safety Equipment Supply in UAE.Safety first should be the motto of any shipping company